Welcome To Roots Agriculture!

Blog

IQF technology and Food preservation techniques

The preservation of food for long-term storage is a classic example of human inventiveness. Freezing is possibly the most popular approach to preserve food in the modern world.

When it comes to vegetables, freezing not only preserves the nutritional value of the vegetable, but it also often enhances the flavour, Frozen food allows customers to store their favourite foods for extended periods of time.

When it comes to the bleeding edge of technology in frozen food applications, there may be no better technique than IQF.

What do you mean by IQF?

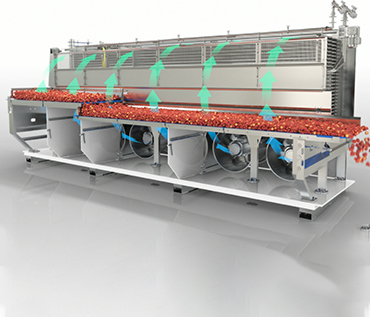

The individually quick-frozen (IQF) method of freezing. IQF is a method that prevents large ice crystals from forming in vegetable cells. Furthermore, because each piece is frozen separately, particles do not cohere, and the final product is not frozen into a solid block, and this makes it effortless to select as large a portion of frozen goods as you need when cooking, for instance.

Are there any other freezing techniques besides these?

Vegetables and fruits are widely preserved using various freezing procedures. Blast freezing, plate freezing, belt-tunnel freezing, fluidized-bed freezing, cryogenic freezing, and dehydrofreezing are examples. The method chosen is determined by the intended final product quality, the type of vegetable to be frozen, capital limitations, and whether the products are to be stored in bulk or in individual retail packets.

Advantages of IQF freezing

- Prevents damage and protects the products that are frozen with it. IQF ensures that the food being frozen freezes while generating almost no ice crystals within the product itself.

- Unparalleled customer simplicity of use. The ability to easily separate frozen food into individual pieces and extract only what is needed is extremely handy for rapidly preparing meals or saving time in the kitchen. Instead of attempting to slice or chisel away at a half-frozen piece of meat, you may now remove as many pieces as you need and save the remainder for later.

- There's another huge advantage of IQF technology that's hard to match elsewhere. Specifically, the size of the ice crystal formation. While this may appear to be a minor technical change, it has a significant impact on the flavor, color, texture, and even fragrance of the frozen product. Here's how it's done: When you freeze products in a different way, the frozen water usually turns into ice, and this ice is formed of ice crystals with extraordinarily small sizes.

- This directly benefits chain restaurants and culinary businesses that rely on availability and timeliness as key success factors. As a result, the presentation is much more inviting.

What Foods Are Frozen with IQF?

Theoretically, you can use IQF to freeze any food product. Still, the most common types of food that are regularly frozen with individually quick frozen technology include, but are not limited to, French fries, peas, corn, strawberries, blueberries, raspberries, blackberries, lobster, shrimp, oysters, clams, pork, chicken, beef, bison, and various other types of produce, meats, poultry, and foods that are prone to spoilage if not preserved.

What methods are most used in Egypt? and what differs them from one another?

The common techniques that used in Egypt are IQF and blast freezing, Individual quick freeze (frozen), or IQF is a freezing process performed by blast freezers. As the name suggests, IQF is a form of freezing in which multiple products are frozen in the same area, but each and every product individually freezes within the same space of other products.

IS IQF better?

IQF is a technique that permits the freezing on an individual piece of goods separately from the others. As a result, the finished IQF product has a higher quality compared to a product frozen via cold storage freezing.

Subscribe to newsletter